We have observed in the past that technologies have changed continuously and managed to squeeze itself into a scaled-down and concise structure. Let’s take among the principal computers that were made were the size of a warehouse of 1000 laptops which we use today. Consider how it is been turned possible? The solution to it’s integrated circuits.

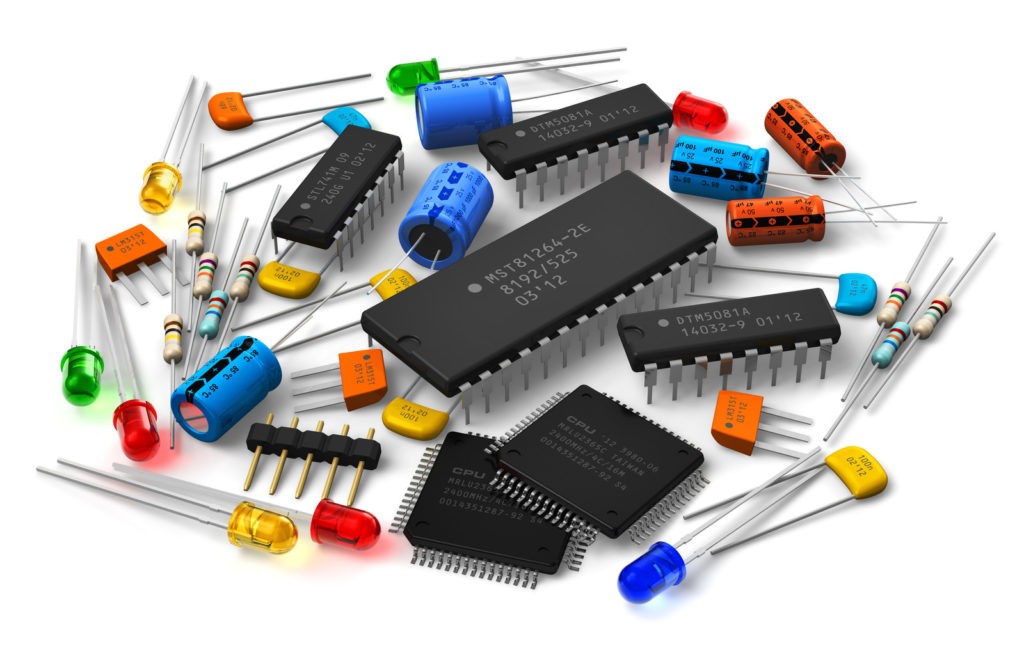

The circuits that were made previously were large and ponderous, having a circuit components like resistor, transistor, diodes, capacitor, inductor, etc. that had been connected alongside copper wires. This factor limited the utilization of the circuits to big machines. It was impossible to create small and compact appliances using these big circuits. Moreover, they weren’t entirely shockproofed and reliable.

As mentioned, necessity could be the mother coming from all inventions, similarly, the newest technologies each is the result of it. There is a necessity to formulate circuits of smaller size with increased power and safety to feature them into devices. Then were three American scientists who invented transistors which simplified items to quite a degree, nonetheless it was the development of integrated circuits that changed the face of electronics technology.

What is Integrated Circuit?

A circuit (IC), sometimes it could be referred to as a chip or a microchip is often a compilation of transistors that are positioned on silicon. A circuit is way too small in proportions, when it’s in comparison to the standard circuits that are created from the independent circuit components, to expect the dimensions of a fingernail. IC is really a semiconductor wafer (also called a thin slice of semiconductor, for example crystalline silicon) where thousands or millions of tiny resistors, capacitors, and transistors are fabricated.

Modern electronic circuits aren’t made up of individual, means they is not consisting of separated components as used to be the situation. Instead, many small circuits are embedded in a single complex piece of silicon as well as other materials called a built-in circuit(IC), or chip or microchip. The production of integrated circuits commences with a straightforward circular wafer of silicon several inches across.

Firstly designers made drawings of in which each take into account each section of the circuit would be to go in order that the processing would become easy. A photo of each and every diagram is then reduced in space repeatedly to supply a smaller photolithographic mask.

The silicon wafer is coated with a material known as a photoresist that undergoes a compound process when exposed to ultraviolet light. Ultraviolet light shown over the mask on top of the photoresist creates a similar pattern around the wafer as similar to that mask. Then solvents etch to the elements of the resist that were subjected to the lighting, leaving another parts intact. Then another layer of a silicon material doped by incorporating impurities so that it is set on top of the wafer, and another pattern is etched in with a similar technique.

The effect of these operations is often a multilayered circuit, with lots of countless tiny transistors, resistors, and conductors created inside the wafer. The wafer will then be broken apart along prestressed lines into many identical square or rectangular chips, that’s no more integrated circuits.

Check out about Electronic components explore our website