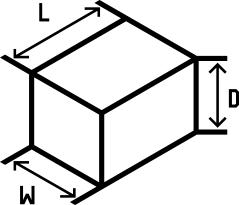

Whether your concrete need is as small as needed for fixing cracks and holes within the wall, constructing a patio, paving, pathway, or as huge as a construction of a high-storey commercial building, the initial step to start is simply by ordering the complete volume of concrete needed. It comes down because next point that the way the ordered concrete must be delivered to your work site. While most projects are measured in sq . ft ., once you place an order for concrete, it’s done in cubic yards. Measure the proportions of the web page to look for the right number of concrete needed.

First you have to multiply the size of the project by width, then multiply the resultant figure by depth (meaning thickness), and divide it by 27 to learn how much concrete needed in ‘cubic yards’ unit. Finding it hard to calculate on own? There are several websites featuring online concrete calculator. Or you can always speak to your local concrete supplier company to ensure that a concrete specialist can click on the web page face-to-face and help you determine the correct amount of concrete mix required for assembling your project; this strategy will assist you to avoid under-ordering and over-ordering scenarios. Many concrete suppliers offer on-site assistance right from determining the appropriate volume, onsite concrete mixing and application to refurbishment of the concrete structures. Now when you’re conscious of how much concrete you’ll need, the next step would be to select how to get the task finished. Concrete as we all know is really a mix of Portland cement, sand, gravel and water. Other aggregates may be added with the supplier company depending on assembling your shed specifications.

Why Choose Ready Mix Concrete For your Construction Needs

Now, before sharing the 12 time-tested tips to achieve your construction project, it can be worth mentioning here that ordering ready mix concrete London is much better than mixing concrete onsite. Even if you pay more ready mix also is called able to lay concrete, it’s pool of benefits like there is no need of space for storing, instant application, faster construction, reduced demand for workforce, top-quality and sustainability turn it into a smarter alternative. Moreover, the concrete supplier companies are serving any big and small size order of ready mix concrete. So, both DIY residents and contractors can leverage by reviewing the advantages. Simply put, pre-made concrete decreases the focus on site, raises the quality and finished of training, and fast-track the job accomplishing.

Top 8 How to Prevent Failure Within your Construction Project

Don’t order under what exactly you need

Cover concrete using plastic or damp fabric to avoid cracks

Add colour and additive straighten; you can also reduce curing period

Concrete mix might require reinforcement of steel bars, wire mesh, etc. to improve strength; consult a concrete specialist to acquire more information.

For DIY project, use safety wear to guard eyes, nose and skin through the harmful effects

Adding more level of Portland cement can use a stronger solution of the concrete mix

For a moment need concrete during Christmas or perhaps in holidays, check if the supplier you decide on are open through the festive season or otherwise not; if that’s the case, it is recommended schedule delivery ahead of time. Planning advance will avoid extra charges and all hassles.

As it were need concrete pumps to transport concrete mix on the spot, prepare yourself and hire concrete pumps while ordering the mix

Hope the following tips will assist you to order concrete mix the correct way!

For additional information about concrete mix calculator please visit resource: visit site.