The term pcb assembly refers back to the process of attaching various electronic components with a pcb to produce and finish a completely functional printed circuit assembly. Basically, there’s two kinds of construction found in this method, an example may be the surface-mount construction, and yet another could be the through-hole construction. Those two methods have individual benefits when utilize. The surface mount technique consumes less space, while through-hole mounting provides strength for virtually any component that is likely to endure physical stress from the unit. Nonetheless, the two of these methods their very own advantages and drawbacks within the integral procedure for assembly.

Assembly: Briefly

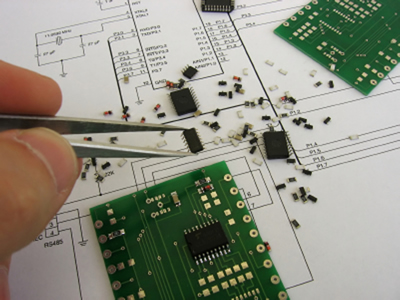

PCBs are employed to mechanically connect and support various electronic components by utilizing different conductive pathways, methods, tracks and traces. These elements are effectively etched from laminated sheets of copper onto a non-conductive substrate. Furthermore, once the overall PCB process is fully gone then electronic components attach to produce these assembly. The component leads are carefully inserted through the holes in the PCB as well as the surface mount construction, and the electronic components they fit about the external pads of the printed circuit board. Lastly, PCB fabrication manufacturer leads in kinds of this construction are mechanically fixed to the PCB by using soft metal molten solder.

The assembly process involves various types of methods for attaching the parts to the. In case a high volume production is necessary, it’s mainly made by bulk wave soldering, machine placement or with the aid of reflow ovens. A mechanical assembly service expert produces the assembly unit while using the above discussed methods and materials.

In this modern electronic and technological world, pcb assembly services would be the key to the electronics sector due to utility and efficiency they provide. A printed circuit board is definitely an electronic unit which is used for connecting electrical elements into various appliances and machinery. They are usually seen in the majority of the electrical devices like games, computers, i-Pods, consoles, televisions and the like. However, to the output of large electronic devices, electronic manufacturers often hire professional assemblers from authorized PCB assembly services to complete the job.

What is the Great need of PCB Assembly?

These products are very important given that they can upgrade any digital camera or gadget without any difficulty.

The word prototype PCB assembly refers back to the technique of attaching various electronic components to some printed circuit board to produce and handle a fully functional printed circuit assembly. Basically, there’s two varieties of construction found in the whole process of PCB assembly, the first is the surface-mount construction, and yet another may be the through-hole construction.

To learn more about China PCB assembly take a look at this useful web portal.